- November 2, 2023

- Posted by: Dyaneshwar Nirmale

- Category: Uncategorized

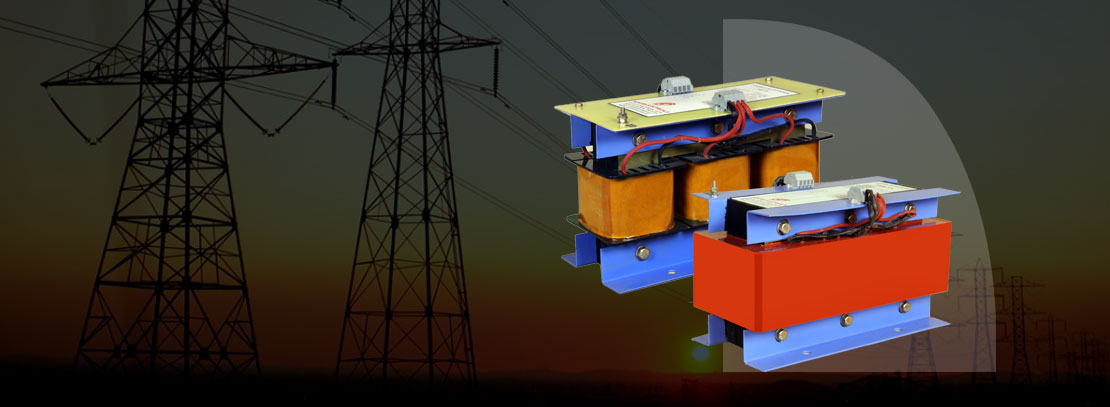

Control transformers play a crucial role in electrical systems, providing voltage regulation and isolation for various devices. These transformers are widely used in industrial and commercial applications to control the voltage levels required for efficient operation. In this article, we will explore what control transformers are, how they work, and their importance in electrical systems.

What is a Control Transformer?

A control transformer, also known as an instrument transformer, is a type of transformer specifically designed to regulate voltage levels in control circuits. It is primarily used to step down high voltage to a lower, more manageable voltage suitable for powering control devices. Control transformers are commonly found in industrial machinery, HVAC systems, motor control centers, and other applications where precise voltage control is necessary.

How Does a Control Transformer Work?

Control transformers operate on the principle of electromagnetic induction, similar to other types of transformers. They consist of two windings: a primary winding and a secondary winding. The primary winding is connected to the high-voltage side of the circuit, while the secondary winding is connected to the low-voltage side, where the control devices are located.

When an alternating current (AC) flows through the primary winding, it creates a magnetic field in the transformer’s core. This magnetic field then induces a current in the secondary winding through mutual inductance. The number of turns in the secondary winding is typically greater than in the primary winding, creating a step-down ratio that reduces the voltage to a level suitable for control applications.

Construction of Control Transformers

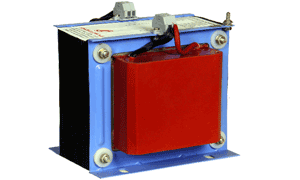

Control transformers are constructed using high-quality materials to ensure reliability and long-term performance. The primary and secondary windings are typically made of copper or aluminum conductors, chosen for their excellent electrical conductivity. The windings are insulated to prevent electrical leakage and ensure safe operation.

The core of a control transformer is made from laminated sheets of high-grade electrical steel. These laminations help reduce energy losses and minimize the effects of magnetic hysteresis and eddy currents. The core is designed to provide a low reluctance path for the magnetic flux generated by the primary winding.

To protect the windings and core, control transformers are housed in a sturdy enclosure, often made of steel or other durable materials. The enclosure provides insulation and mechanical protection, safeguarding the transformer from external factors such as moisture, dust, and physical damage.

Voltage Regulation and Control

One of the key functions of a control transformer is voltage regulation. It ensures that the control devices receive a stable and consistent voltage, regardless of fluctuations in the input voltage. This is crucial for the proper operation of control systems, as variations in voltage can lead to erratic behavior and malfunctioning of the devices.

Control transformers achieve voltage regulation through the use of tap settings. These tap settings allow the transformer’s output voltage to be adjusted within a specified range. By changing the tap connection, the voltage can be increased or decreased to meet the requirements of the control circuit.

Isolation and Safety

Control transformers also provide electrical isolation between the primary and secondary circuits. This isolation ensures that the control devices and operators are protected from the high voltages present on the primary side of the transformer. It helps prevent electrical shocks and reduces the risk of damage to sensitive control equipment.

Isolation is achieved by the physical separation of the primary and secondary windings and the insulation materials used in the transformer’s construction. The insulation materials are chosen to withstand the high voltages and provide a reliable barrier between the primary and secondary circuits.

Control Transformer Applications

Control transformers are used in a wide range of applications, where precise voltage control and isolation are essential. Some of the common applications include:

- Industrial Machinery: Control transformers are used in various industrial machinery, such as conveyor systems, pumps, and motors. They provide the necessary voltage regulation and isolation to ensure smooth operation and protect the control devices.

- HVAC Systems: Heating, ventilation, and air conditioning (HVAC) systems often require control transformers to regulate the voltage for control circuits. These transformers help maintain optimal temperature and airflow control in commercial and residential buildings.

- Motor Control Centers: Control transformers are an integral part of motor control centers (MCCs). MCCs are used to control and protect electric motors in industrial applications. The transformers provide the voltage levels required for motor control and ensure safe operation.

- Lighting Control Systems: Control transformers are used in lighting control systems to regulate the voltage for dimming and switching operations. They enable precise control of lighting levels in commercial buildings, theaters, and other venues.

Benefits of Control Transformers

Control transformers offer several benefits that make them indispensable in electrical systems. Some of the key benefits include:

- Voltage Regulation: Control transformers ensure that control devices receive a consistent and stable voltage, regardless of fluctuations in the input voltage. This helps maintain the accuracy and reliability of control systems.

- Isolation: The electrical isolation provided by control transformers protects control devices and operators from high voltages on the primary side. It reduces the risk of electrical shocks and prevents damage to sensitive equipment.

- Compact Size: Control transformers are compact and designed to fit into limited spaces. Their small size makes them ideal for applications where space is a constraint.

- Versatility: Control transformers can be customized to meet specific voltage and power requirements. They can be designed for different input and output voltages, ensuring compatibility with various control devices.

Control Transformer Manufacturers

When selecting a control transformer, it is essential to choose a reputable manufacturer that provides high-quality products. Newtek Electrical, a leading manufacturer of current transformers, potential transformers, and digital meters, offers a wide range of control transformers. Their transformers are fabricated using advanced materials such as nylon and resin cast for added protection. Newtek Electrical consistently upgrades their technology to maintain premium quality standards.

In conclusion, control transformers play a vital role in electrical systems, providing voltage regulation, isolation, and safety for control circuits. They are widely used in industrial machinery, HVAC systems, motor control centers, and lighting control systems. By ensuring stable voltage levels and protecting control devices, control transformers contribute to the efficient and reliable operation of electrical systems.