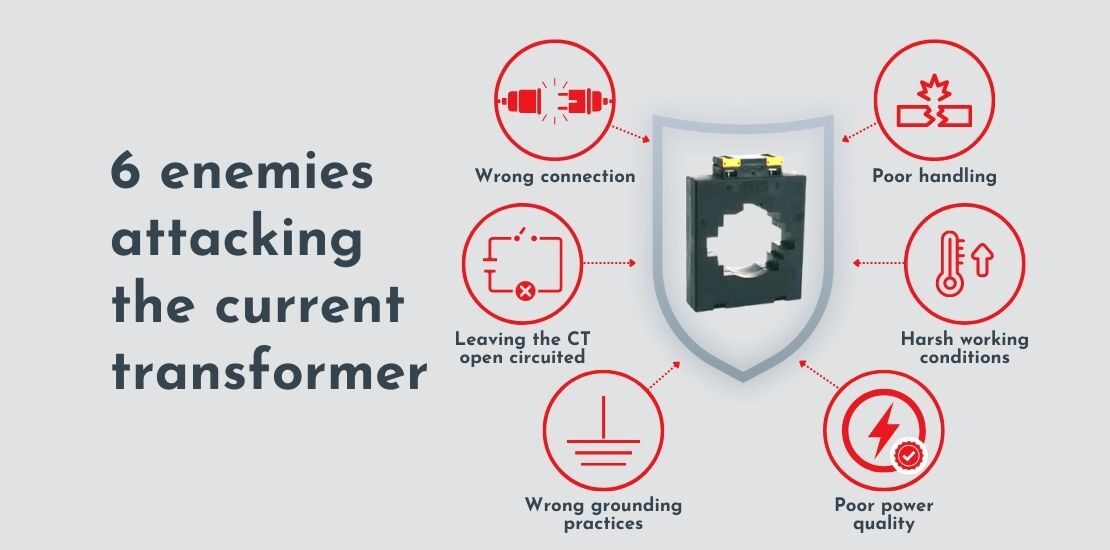

6 enemies attacking the current transformer

- May 8, 2022

- Posted by: Dyaneshwar Nirmale

- Category: Digital Meters

The current transformer is no less than a Hollywood hero!

Think about it. It takes the perils of high-voltage power onto its own body and steps down the power so that ordinary devices can use it. At the same time, it isolates the smaller devices from power problems while exposing themselves to them, often working in harsh conditions, high temperatures, and remote corners.

The CT has the immense caliber and quality, but akin to a real hero, the CT is also surrounded by powerful enemies who are constantly trying to bring it down.

Who are the 6 major enemies of the current transformer?

Wrong connection

Poor and wrong connections can cause irreversible damage to the current transformer. Some of the common connection mistakes include leaving the CT open-circuited or miscalculating the grounding connection of the current transformer.

Leaving the CT open circuited

When the secondary circuit is an open circuit as shown in fig. (c), a very high back Emf voltage is generated according to Lenz’s law of electricity. This couuenr could give a deadly shock to the person handling the open-circuited CT, and in more serious cases, could lead to a fire incident and explosion.

Explore the issue in detail here

Wrong grounding practices

A major misconception about the grounding of electrical devices is that the higher the number of grounding connections, the safer the electrical network is. Due to this belief, when multiple current transformers are used, each current transformer is often given its own grounding connection.

However, this practice could be counter-productive

Current transformer secondary grounding is done at multiple points does not exactly cause any issues under normal conditions. However, in case of a fault, the potential at the different grounding points of the current transformer will rise at different rates. This leads to a high current flow through the CT circuit, and this current is not representative of the primary current. This makes the relay believe that there is a fault in its protective zone, and trip.

Such nuisance trips not only shut down the load but also lead maintenance personnel to waste time in finding fault in the differential relay when there exists none in reality.

If multiple current transformers are provided with a separate grounding, the level of a potential rise in each of the current transformers will be different. In such cases too, the relay will trip even when there is no fault in the protection zone. In order to avoid such a situation, it is recommended that the current transformer’s secondary grounding should be done at a single point.

Learn the correct way of grounding the current transformer

Poor power quality

All of the electronic, as well as electric infrastructure created in recent years, is very sensitive to power quality. Poor power quality can lead electronic devices to fail, malfunction, and lose data. However, it can also damage distribution equipment including current transformers.

The emergence of power quality issues such as harmonics leads to eddy current loss in the transformers that supply power to harmonic-producing non-linear loads. These eddy current losses lead the transformers to heat up, which can reduce the lifespan of the current transformers or even cause them to fail.

Learn more about 8 major power quality problems here

Poor handling

Current transformers often fall down in the course of mounting or handling activity. This leads to cracks or complete breaking of the components. Replacing them entails considerable time and costs. Newtek nylon casing CTs do not develop such cracks of breaks after falling. The tough nylon material absorbs the impact of the fall and protects the current transformer located inside.

Harsh working conditions

Harsh working conditions are again tied to the quality and make of the current transformer. High temperatures could reduce the lifespan of the current transformer. In case of incidents, such has fire, a poor quality transformer is quickly damaged.

Nylon case current transformers use Nylon Flame Retardant Material (Nylon 66). Thus, they can withstand temperatures up to 180 degrees C. and VCAT softening temperatures of around 240 degrees C. On the other hand, ABS material used for conventional transformers can withstand only around 110 degrees C.

In some cases, it becomes difficult to install conventional current transformers in pre-designed panels. Nylon cast transformers are designed to resolve this issue. Newtek nylon casing current transformers have much lesser outside diameter than any other conventional CT. Thus, our nylon casing transformers occupy much lesser space.