Reduce the losses to improve current transformer efficiency

- May 16, 2022

- Posted by: Dyaneshwar Nirmale

- Category: Digital Meters

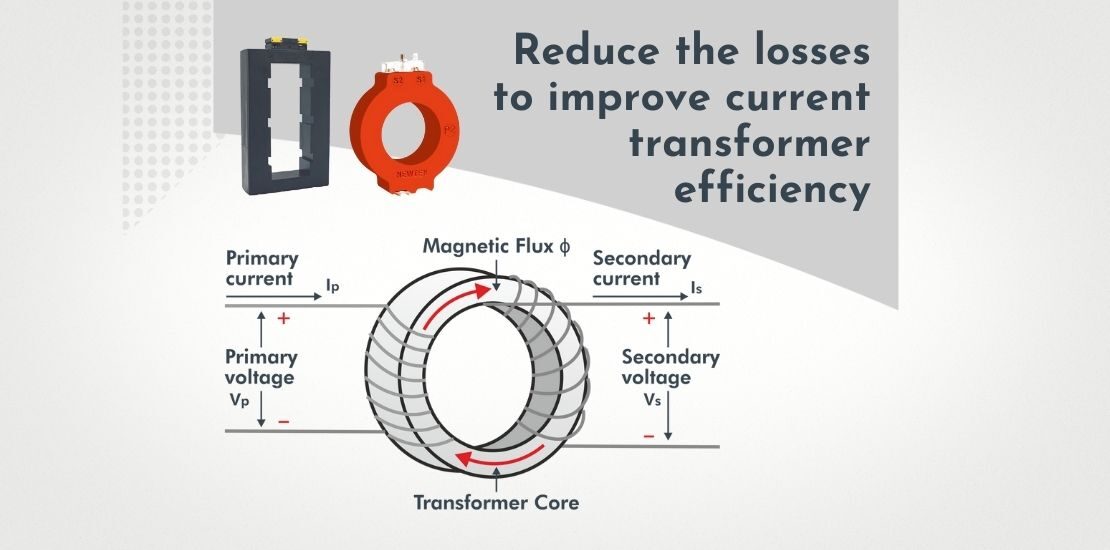

Current transformers are critical to maintaining the safety and efficiency of an electrical network. They must step down the power so that it could be accurately measured and used in the relevant applications. A small measure to improve current transformer efficiency could thus result in significant improvement in the performance of the downstream electrical network.

Power losses in current transformers

Theoretically, current transformers should be 100% efficient with zero losses of power. However, in reality, certain losses do occur, and the CTs possess between 95% ro 98% efficiency. Losses in a current transformer can be classified into two types:

- Load losses: Losses that occur due to the resistance in current transformer windings

- No-load losses: Losses that occur due to resistance in the current transformer core.

The maximum efficiency of the current transformer is decided based on the relative value of these losses. An ideal transformer should have an efficiency between 98%-99.5 %. A highly efficient transformer requires less cooling and hence saves energy.

How to reduce current transformer losses

No-load losses

Since they originate from the current transformer core, no-load losses are also called core losses. The current transformer core is generally made up of steel which has around 3% of silicon. This silicon gives the core high resistivity. Apart from this composition, the thickness of the core determines the amount of eddy current losses while the core permeability decides hysteresis losses. A higher permeability and a thinner core material in the core helps minimize the no-load losses. However, high-permeability thin core material could drive up the current transformer cost.

Load losses

Load losses occur due to increased resistivity in the current transformer windings. There are a number of sub-constituents to load losses.

Stray losses

Stary losses emerge due to the leakage flux. Factors such as the size and spacing of the winding, the position of clamps etc. THe presence of a shield or shunt also determines the extent of stray losses. Lastly, along with the coil flux, there is also flux produced by the leads.

I²R losses

I2R losses is the computed value of resistivity. The losses are measured at a constant temperature of 75 degrees C, and could vary according to the current density used.

Eddy current losses

Eddy current losses occur due to simple principle in Fereday’s Law which states that “Any change in the environment of a coil of wire will cause a voltage to be induced in the coil, regardless of how the magnetic change is produced.” Hence, the rotation of a motor core in a magnetic field induces an EMF into the coils. This in turn leads to the flow of circulating currents which are known as eddy currents. The power loss caused by these currents is known as eddy current loss.

Winding losses

Wrong positioning or defect in the windings could be a cause of winding losses. If two or more wires in parallel are used to make a coil, their positions should be interchanged along the windings in order to cancel the induced voltage generated by the stray flux. If this is not done, the net induced voltage will drive current around the established loop and these circulating currents will increase the losses.

Conclusion

Coming back to the basics, the build quality of the current transformer is the key to transformer efficiency. The stacked core of the current transformer needs joints that change the direction of induction and create a gap between different laminations. Hence, multiplying the core loss specified by the supplier at operating flux density by total core weight yields a value lower than that measured in the assembled core.

Factors such as burrs, cutting, types of joints used, the type ad grade of materials used, etc influence the losses. Cruttent transformer procurement should thus be done after consultation with current transformer manufacturing experts. This is where Newtek and its technology help meet your needs.

Backed by 10+ years of experience, Newtek Electricals provides innovative nylon-encased current transformers that are more efficient and reliable than conventional current transformers in every way. Newtek nylon casing current transformers are designed to be resistant to fire and damage from fall while offering consistent performance. Additionally, innovations in production technology allow Newtek to deliver the best quality current transformers in the shorotest possible lead time.