- September 23, 2021

- Posted by: Dyaneshwar Nirmale

- Category: Digital Meters

This one mistake in connections can turn your CTs into dangerous devices!

Achieving high energy efficiency and good power quality is the top concern for businesses at a time when billing has shifted from KWh to KvAh. Monitoring and analysis of certain electrical parameters such as voltage, power factor, harmonics etc are vital for early detection of faults and maintenance of power quality. Multifunction meters play a key role in measuring these parameters and thus help businesses craft a strategy to save their power costs.

Newtek Electrical provides durable and reliable multifunction meters enabled with MODBUS RS 485 communication system to accurately record your power consumption and transfer it to a computer for further analysis.

The present blog discusses how to effectively use a Newtek multifunction meter with MODBUS RS 485 communication system.

A system fit for submetering

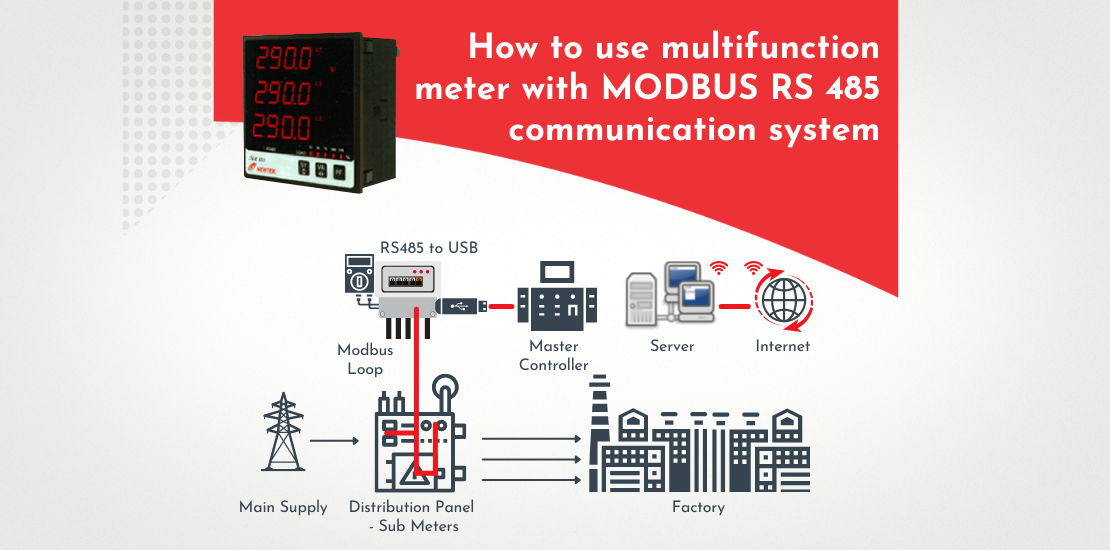

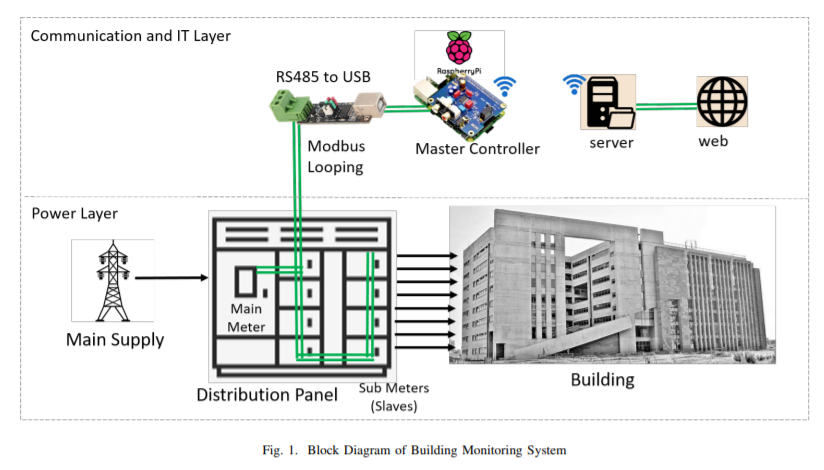

Multifunction meters monitor key power parameters. Hence, they are used in commercial as well as manufacturing facilities for submetering. The power is passed through the entire building from the main power supply, and the main meter records the power consumption for the entire building. Additionally, there could be more meters installed on each floor or in each department to monitor their power consumption patterns in detail. All of the data recorded by these submeters are collected in one place and analysed for decision-making.

The multifunction meters on each floor record the power consumption data as well as power parameters and communicate them to a central SCADA system using the MODBUS RS 485 communication system.

A MODBUS looping wire is connected to all the multifunction meters in the communication layer. A master controller is connected to the setup through an RS485 to USB converter, and the meters act as slaves.

Why RS 485?

Many modern smart meters come with inbuilt IP connectivity. However, RS 485 remains the most commonly used communication protocol in India. It is the most optimal communication protocol for facility networking. In case an Ethernet is used, a number of switching hubs and UTP cables must be deployed. Newtek multifunction meters also come with dedicated software to make data retrieval and analysis easy and simple.

Extracting data from the multifunction meter with MODBUS RS 485

Data can be extracted from Newtek multifunction meter with MODBUS Rs 485 using simple steps.

To begin with, configure all of your submetering multifunction meters. Assign each of them a unique slave ID, and set other parameters such as baud rate, number of data bits, number of start bits, and parity. The setting can be done manually using the keys on the meter or through software using a data port.

Next, the multifunction meters must be looped correctly to the MODBUS loop and connected to the microcontroller via RS485/USB interface. The microcontroller should have the code for communication stored within it. If it is not, code the controller accordingly, and it will be executed once the meters are connected. The data collected by the multifunction meters will be written into the files within a centralized server.

What we offer

Newtek electricals has over a decade of experience in designing and manufacturing reliable, durable, and high-performing multifunction meters. Newtek multifunction meters also come with dedicated software to make data retrieval and analysis easy and simple. Customers can choose from 8 different models of diverse capacity multifunction meters available with us to select a multifunction meter as per their application needs.