- February 3, 2021

- Posted by: Dyaneshwar Nirmale

- Category: Digital Meters

Resin cast current Transformers

Resin cast current transformers are a type of dry transformer where the internal components are enclosed in epoxy resin within a vacuum chamber. This process guarantees consistent and reliable insulation. The resin hardens, ensuring the safety of your electrical equipment. These transformers are commonly employed for insulating high-voltage electrical components.

Cast resin dry type transformers are preferred tools when it comes to measurement and control of power in many business sectors. Newtek Electricals is a leading manufacturer and supplier of resin cast current transformers in India. They are most popular for their ability to perform optimally in dusty scenarios. Their quality, durability, and performance gives resin cast current transformers a number of advantages over other types of transformers.

Features of Resin cast transformers

- Resin cast CTs have their internal components encapsulated in epoxy resin within a vacuum chamber.

- The epoxy resin casting provides exceptional insulation properties, protecting the CT against environmental factors and ensuring a longer lifespan.

- The resin cast process hardens the epoxy resin, making it durable and robust.

- Resin cast CTs are commonly used for insulating high-voltage electrical components, ensuring accurate and safe current measurement

- The epoxy resin provides resistance against moisture and corrosion, making resin cast CTs suitable for harsh environments.

- Resin cast CTs are compact and lightweight, which simplifies installation and maintenance.

- The Resin CTs require minimal maintenance, primarily because of their solid and sealed construction.

- Resin cast CTs are available in different voltage classes, making them suitable for a wide range of applications.

Resin cast CTs have their internal components encapsulated in epoxy resin within a vacuum chamber. This process ensures uniform and reliable insulation, enhancing safety for electrical equipment. know more advantage of resin cast current transformers (CT).

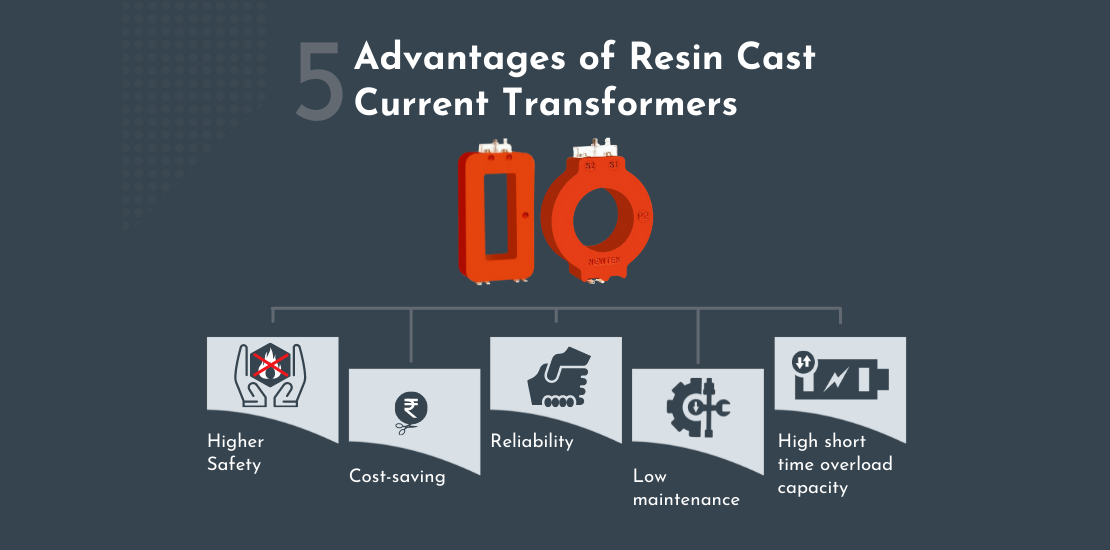

Here are 5 key advantages of resin cast transformers.

Higher safety with Resin Cast CTs

The insulation of resin cast transformers itself works to reduce the risk of fire due to its special material composition. It is made up of epoxy resin and quartz powder mixture. The fire retardant material leads the flames to self-extinguish and prevents the damage from spreading. Secondly, as resin cast CTs do not use oil, the risk of explosion is close to nil.

Cost-saving with Resin Cast CTs

Newtek Resin cast current transformer is completely maintenance-free, eliminating your maintenance costs. Added features provided for easy installation also mean little to no installation costs.

Reliability of Resin CTs

Resin material in the current transformer offers them high capacity to withstand the extreme and abrupt changes in temperatures. They could easily withstand a sudden temperature change from -25degrees C to 40 degrees C, and still keep up the optimal performance. These transformers are originally built to perform between ranges of -50 to 50 degrees C. The resin made of the transformer also prevents moisture from penetrating inside the component. This makes it a perfect fit for use in hazardous environments. Resin cast transformers have a long service life of around 20 years.

Low maintenance of Resin Cast CTs

Dust buildup inside the transformer is prevented swiftly by the smooth coil surface of the resin cast transformer. This, combined with the absence of oil-related maintenance tasks, makes resin cast CTs almost maintenance-free. It is however advised to conduct a routine visual inspection and thorough wipe-down of the current transformer to ensure consistent performance.

High short-time overload capacity

Axial and radial forces under high current loads do not affect the resin cast transformers. This happens simply because the winding of resin cast transformer is encapsulated in resin. This mechanism allows resin cast transformers to tackle short time overloads far better than oil-cooled transformers.